Unlocking the Secrets of Gas Analysis: Understanding the Science and Technology Behind Gas Analyzers

Gas analysis plays a crucial role in many industries, from oil and gas production to environmental monitoring. The ability to accurately measure the composition of gases is essential for ensuring safety, optimizing production, and protecting the environment. In this article, we will explore the science and technology behind gas analyzers and explain how they work.

Introduction to Gas Analysis

Gas analysis is the process of measuring the composition and characteristics of gases. The analysis is used in many industries, including manufacturing, healthcare, environmental monitoring, and oil and gas production. The analysis of gases helps in identifying and quantifying the presence of different gas components, and it provides data on the purity of gases and their suitability for specific applications.

The Need for Gas Analysis

Gas analysis is needed in many industries, including those involved in the production, transportation, and distribution of natural gas and petroleum products. In these industries, gas analysis helps in identifying impurities in the gas stream that could harm equipment or pose safety risks to workers. Gas analysis is also needed in the environmental monitoring industry to track the emission of pollutants from industrial sites and other sources.

Understanding Gas Analyzers

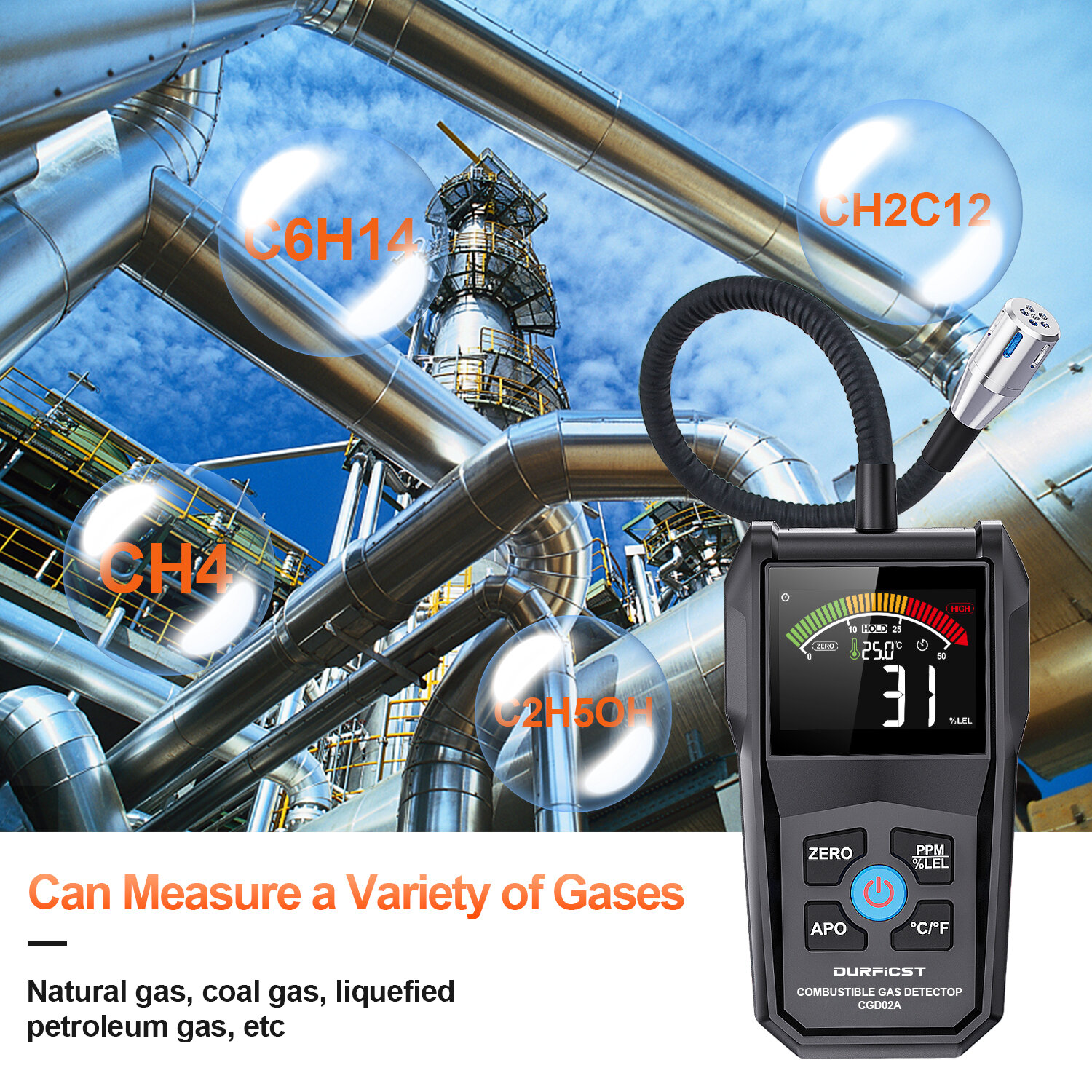

Gas analyzers are devices that use various technologies to measure the composition of gases. There are several types of gas analyzers, including infrared, thermal conductivity, flame ionization, and mass spectrometry analyzers. Each of these analyzers has its own strengths and weaknesses, and their selection depends on the specific application requirements.

Infrared Gas Analyzers

Infrared gas analyzers measure the concentration of gases by detecting the absorption of infrared light. The technique works by shining a beam of infrared light through a gas sample and measuring the amount of light absorbed by the gas components. Infrared gas analyzers are commonly used in the petrochemical industry to measure the concentration of hydrocarbons.

Thermal Conductivity Gas Analyzers

Thermal conductivity gas analyzers measure the concentration of gases by detecting changes in thermal conductivity caused by the presence of gas components. The technique works by measuring the thermal conductivity of the gas sample in a reference cell and comparing it with the thermal conductivity of the gas in a measuring cell. Thermal conductivity gas analyzers are commonly used in the semiconductor industry to measure the concentration of impurities in process gases.

Flame Ionization Gas Analyzers

Flame ionization gas analyzers measure the concentration of hydrocarbons by detecting the ionization produced by the combustion of the gas sample. The technique works by burning the gas sample in a flame and measuring the current produced by the ionization of the hydrocarbons. Flame ionization gas analyzers are commonly used in the oil and gas industry to measure the concentration of hydrocarbons in gas streams.

Mass Spectrometry Gas Analyzers

Mass spectrometry gas analyzers measure the concentration of gases by detecting the mass-to-charge ratio of gas components. The technique works by ionizing the gas components and then measuring the mass-to-charge ratio of the resulting ions. Mass spectrometry gas analyzers are commonly used in the chemical and pharmaceutical industries to measure the purity of process gases.

Gas Analysis Applications

Gas analysis has many applications in various industries. The following are some of the most common applications of gas analysis:

Oil and Gas Production

Gas analysis is used in the oil and gas industry to monitor the quality of the gas stream and ensure that it meets the required specifications. Gas analyzers are used to measure the concentration of hydrocarbons, water, and other impurities in the gas stream.

Environmental Monitoring

Gas analysis is used in environmental monitoring to measure the concentration of pollutants in the air, water, and soil. Gas analyzers are used to measure the concentration of gases such as carbon monoxide, sulfur dioxide, nitrogen oxides, and volatile organic compounds (VOCs) that can have harmful effects on the environment and human health. Gas analysis can provide valuable data for understanding the sources and effects of pollution, identifying areas that require remediation, and monitoring the effectiveness of pollution control measures. The data provided by gas analyzers can help governments and industries make informed decisions about environmental policies and practices to protect the environment and public health.

Manufacturing

Gas analysis is used in the manufacturing industry to monitor the purity of gases used in various processes. Gas analyzers are used to measure the concentration of impurities such as moisture, oxygen, and other gases that can affect the quality of the final product.

Healthcare

Gas analysis is used in the healthcare industry to monitor the concentration of gases such as oxygen and carbon dioxide in medical gases. Gas analyzers are used to ensure that the medical gases are of the required quality and purity for use in medical applications.

Factors Affecting Gas Analysis

There are several factors that can affect gas analysis, including:

Interference

Interference can occur when other gases or substances present in the gas sample interfere with the measurement of the target gas component. Interference can lead to inaccurate measurements and affect the quality of the analysis.

Cross-Sensitivity

Cross-sensitivity can occur when the gas analyzer is sensitive to other gas components that are present in the gas sample. Cross-sensitivity can lead to inaccurate measurements and affect the quality of the analysis.

Sampling

Sampling is the process of collecting a gas sample for analysis. The sampling process can affect the accuracy and precision of the analysis. Factors such as sample volume, sample flow rate, and sample handling can affect the quality of the analysis.

Conclusion

Gas analysis is an essential tool for many industries, from oil and gas production to environmental monitoring. Gas analyzers use various technologies to measure the composition of gases and provide data on the purity of gases and their suitability for specific applications. Understanding the science and technology behind gas analyzers is essential for selecting the right analyzer for a specific application and ensuring accurate and reliable gas analysis.

FAQs

1. How do gas analyzers work?

Gas analyzers use various technologies such as infrared, thermal conductivity, flame ionization, and mass spectrometry to measure the composition of gases.

2. What are the applications of gas analysis?

Gas analysis has many applications, including oil and gas production, environmental monitoring, manufacturing, and healthcare.

3. What factors can affect gas analysis?

Factors that can affect gas analysis include interference, cross-sensitivity, and sampling.

4. Why is gas analysis important?

Gas analysis is important for ensuring the quality and purity of gases used in various industries and applications.

5. What is the most commonly used gas analyzer?

The most commonly used gas analyzer depends on the specific application requirements, and different types of gas analyzers have their own strengths and weaknesses.

Leave a Comment